- Why Border Rejections Happen: The Critical Role of Accurate Labeling

- Understanding US Import Labeling Requirements: The Non-Negotiables

- Documentation and Compliance: Beyond the Label Itself

- Practical Steps to Avoid Costly Rejections

- Quick-Reference Pre-Shipment Checklist

- Jade Premium's Approach: Expertise That Prevents Problems

- Transforming Mistakes into Success

Last March, a specialty food importer watched helplessly as their entire shipment of premium Chinese soy sauce—worth over $50,000—sat detained at a U.S. port. The culprit? A single missing word on the product label: “soybeans.” The allergen declaration listed other ingredients but omitted this critical component, triggering an immediate customs hold. What followed was weeks of delays, storage fees mounting daily, and ultimately, the shipment’s rejection and return to origin.

This wasn’t just a bureaucratic hiccup. It was a textbook case of how one overlooked detail on a food label can derail an entire international trade operation. For importers navigating the complex world of cross-border food trade, stories like this serve as stark reminders: when it comes to labeling compliance, there’s no room for error.

Why Border Rejections Happen: The Critical Role of Accurate Labeling

The reality of international food trade is unforgiving. According to recent customs data, China’s administration alone rejected over 200 shipments of food from the European Union and 154 from the United States in just the first four months of 2025. The most common denominator? Labeling issues and documentation mismatches.

Border rejections typically stem from two interconnected problems: inaccurate or incomplete product labeling, and documentation that doesn’t align with what’s actually being shipped. When customs officials compare your shipping documents against the physical product labels, any discrepancy—no matter how minor it seems—can trigger rejection.

For U.S. imports specifically, the stakes are particularly high. The FDA maintains strict oversight of all imported food products, and they’re not just checking boxes. They’re protecting public health, ensuring transparency, and maintaining consumer trust. If your product documentation or packaging doesn’t match what the country expects, the shipment faces immediate delays or outright rejection.

The pattern is clear: companies that treat labeling as an afterthought rather than a strategic priority pay the price. Conversely, those who invest in getting it right from the start avoid costly mistakes and build reputations as reliable trade partners.

Understanding US Import Labeling Requirements: The Non-Negotiables

When importing food products into the United States, your labels must satisfy a comprehensive set of federal requirements. All labeling and packaging must be informative, truthful, and presented in English—or in the predominant language of a U.S. territory where the product will be sold. Here’s what every compliant food label must include:

Product Identity: The label must clearly state what the product is. Generic descriptions won’t cut it. If you’re importing Chinese hot sauce, the label should specify “Hot Chili Sauce” rather than just “Sauce.” This identification must be prominent and unambiguous.

Net Quantity Declaration: You must accurately state the product’s net weight or volume using both metric and U.S. customary units. A jar containing 500 milliliters must also show the equivalent in fluid ounces. This information typically appears on the lower third of the principal display panel, in a size proportional to the package dimensions.

Importer Information: Every imported food product must identify the U.S. importer, distributor, or responsible party. This includes the complete business name and physical address—not just a P.O. box. This requirement ensures accountability and traceability should any safety issues arise.

Ingredient List: Ingredients must be listed in descending order by weight. This isn’t optional, and the list must be complete. Remember that soy sauce shipment? The ingredient list was thorough except for the one component that mattered most for allergen purposes.

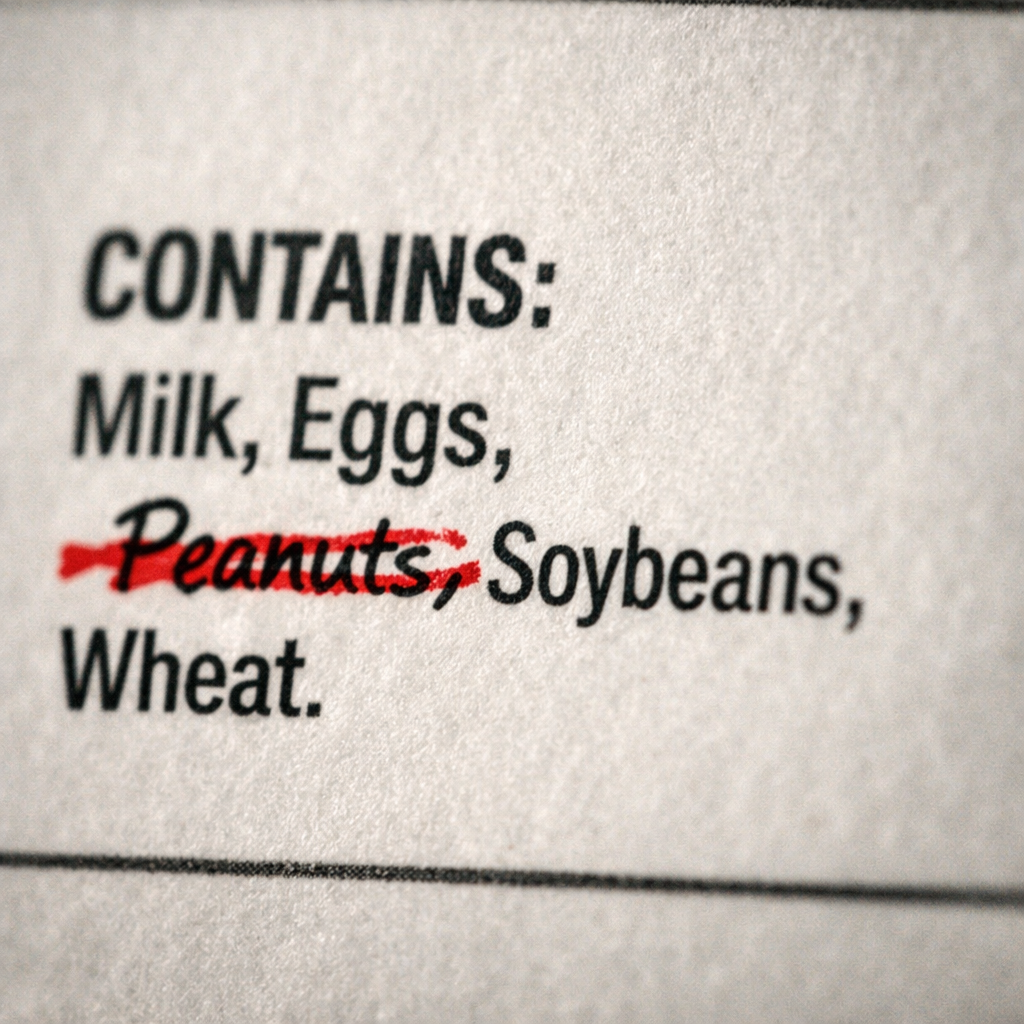

Allergen Declarations: This is where many importers stumble. The FDA requires clear identification of major food allergens: milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, and soybeans. These must be declared either within the ingredient list in plain language or in a separate “Contains” statement immediately following the ingredient list. There’s no wiggle room here—miss one allergen, and you’re facing rejection.

Nutrition Facts Panel: Most food products require standardized nutrition labeling showing serving size, calories, and nutrient content. The format must follow FDA specifications precisely, from font size to panel layout.

Country of Origin Marking: Every item from another country sold in the U.S. must clearly show its country of origin in English. For products made in China, this means prominently displaying “Product of China” or “Made in China” in a permanent, legible manner that stands out to consumers.

The language requirement deserves special emphasis. While additional languages are permitted and sometimes advisable for reaching specific markets, English must be the primary language on all required labeling elements. Some importers think they can bypass this by targeting ethnic communities who speak the product’s native language, but U.S. regulations don’t provide that flexibility.

Documentation and Compliance: Beyond the Label Itself

Even perfect labels won’t guarantee smooth customs clearance if your documentation isn’t equally meticulous. The FDA Prior Notice requirement exemplifies this complexity. Prior Notice must be submitted for all food products imported or offered for import into the United States, providing FDA with advance information about incoming shipments so they can assess potential safety risks.

The FDA uses Prior Notice information to determine which products merit inspection upon arrival. Missing or incorrect Prior Notice filings don’t just delay shipments—they can trigger holds that cascade into storage fees, product deterioration for perishables, and damaged business relationships.

Beyond Prior Notice, food facility registration is mandatory. Any facility that manufactures, processes, packs, or holds food for U.S. consumption must register with FDA. If your Chinese supplier hasn’t completed this registration, your shipment won’t clear customs regardless of how perfect your labels are.

Common causes of documentation-related rejections include:

Incorrect or Missing Certifications: Depending on the product category, you may need health certificates, sanitary certificates, or specific testing documentation for seafood. Meat and seafood products face particularly stringent requirements. Any product that doesn’t meet FSIS requirements for inspections and certifications faces refusal, with importers given just 45 days (30 days for egg products) to destroy the non-compliant goods.

Mismatched Information: When your commercial invoice lists “dried mushrooms” but your label says “shiitake mushrooms,” customs flags the inconsistency. Every document in your import package must tell the same story using consistent terminology.

Non-Compliance with Country-Specific Rules: China’s customs administration recently reported high rejection rates partly due to contamination issues but also improper labeling—missing allergen information and misbranding topped the list. When products move between countries with different regulatory frameworks, ensuring compliance on both ends becomes crucial.

Practical Steps to Avoid Costly Rejections

Prevention beats correction every time in international trade. Here’s how importers can systematically eliminate food labeling rejection risks:

Step 1: Verify Label Content Against Product Specifications

Before production begins, conduct a thorough review matching every label element against actual product characteristics. If your Chinese supplier formulated the sauce with soybean oil, ensure “soybean oil” appears on the ingredient list even if it seems obvious. Create a detailed checklist comparing:

- Product name on label vs. contract specifications

- Complete ingredient list vs. manufacturer’s formula

- Allergen declarations vs. all ingredients that qualify as allergens

- Net quantity vs. actual package contents

- Nutritional information vs. laboratory analysis

Step 2: Engage Regulatory Experts Early

Don’t wait until labels are printed to seek expert guidance. Engaging customs brokers or regulatory consultants during the planning phase helps identify potential issues before they become expensive problems. These professionals understand nuances in regulations that aren’t obvious from reading compliance guides.

For example, certain traditional Chinese food products might contain ingredients that require special declarations or have restricted uses in the U.S. market. Identifying these issues early allows time for formulation adjustments or proper documentation preparation.

Step 3: Implement Pre-Shipment Label Validation

Create a formalized pre-shipment validation process where every label undergoes final verification against current FDA requirements. Regulations evolve, and a label specification that was compliant last year might fall short today. This validation should include:

- Physical label review on actual packaging (not just design proofs)

- Cross-reference with updated FDA guidelines

- Verification that all required elements are present and correctly formatted

- Confirmation that label language meets English primacy requirements

- Check that any additional language versions don’t contradict English text

Step 4: Maintain Meticulous Documentation Alignment

Before shipment, conduct a documentation reconciliation session. Lay out your commercial invoice, packing list, bill of lading, FDA Prior Notice, and product labels. Verify that product descriptions, quantities, and specifications match exactly across all documents. If discrepancies exist, resolve them before the shipment leaves origin.

Step 5: Establish Supplier Quality Partnerships

Work with suppliers who understand international compliance requirements and view labeling accuracy as integral to quality. Suppliers who cut corners on label preparation often cut corners elsewhere too. When evaluating potential partners, ask specific questions about their labeling processes, quality control measures, and track record with U.S. exports.

Quick-Reference Pre-Shipment Checklist

Use this checklist before every shipment to catch potential issues:

- ☐ All required label elements present in English

- ☐ Product identity clearly and accurately stated

- ☐ Net quantity shown in both metric and U.S. units

- ☐ Complete ingredient list in descending weight order

- ☐ All allergens properly declared

- ☐ Nutrition Facts panel formatted per FDA standards

- ☐ Country of origin marking visible and permanent

- ☐ U.S. importer information complete and accurate

- ☐ FDA Prior Notice submitted and confirmed

- ☐ Facility registration current and valid

- ☐ All required certificates obtained

- ☐ Commercial invoice matches label descriptions

- ☐ Packing list reflects actual shipment contents

- ☐ No conflicts between label and other documentation

Jade Premium’s Approach: Expertise That Prevents Problems

This is where the right trade partner makes all the difference. Navigating international food regulations isn’t just about checking boxes—it’s about deeply understanding both the origin market and destination requirements, then bridging that gap seamlessly.

Companies with extensive networks across major Chinese production centers bring invaluable local knowledge to the table. They understand which Chinese producers already meet international standards and which require guidance to achieve compliance. This on-the-ground presence means catching potential labeling issues during production rather than discovering them at customs.

Comprehensive compliance expertise transforms potential obstacles into smooth processes. When trade partners maintain deep knowledge of FDA requirements, FSIS standards, and customs regulations across Asia-Pacific markets, they can guide product compliance transformation from the earliest stages. This includes helping suppliers understand why certain label elements matter, how to obtain necessary certifications, and what documentation customs officials will scrutinize.

Quality control integration represents another critical advantage. End-to-end quality management means verifying not just that products meet safety standards, but that every label accurately reflects what’s inside each package. This attention to detail—inspecting labels as rigorously as inspecting product quality—prevents those costly single-word oversights.

Perhaps most importantly, cultural and market expertise allows for anticipating issues that aren’t obvious from reading regulations. Understanding Chinese food production practices alongside Western regulatory expectations helps identify potential disconnects before they become problems. For instance, knowing that certain traditional Chinese ingredients might require specific documentation for U.S. entry—and preparing that documentation proactively—prevents delays.

The value extends beyond compliance to market intelligence. Beyond facilitating transactions, providing insights into Chinese culinary traditions, export trends, and industry innovations helps international buyers understand not just what they’re importing, but why it matters. This context enriches the import experience and builds stronger, more informed trade relationships.

Transforming Mistakes into Success

That $50,000 soy sauce mistake didn’t have to happen. With proper attention to allergen declarations, thorough label review, and expert guidance, that importer would have caught the missing word before printing thousands of labels. Instead, they learned an expensive lesson about the importance of labeling precision.

The good news? Once companies implement systematic approaches to labeling compliance, rejections become rare exceptions rather than recurring nightmares. Successful importers treat labeling as a strategic priority, invest in expert partnerships, and build processes that catch errors before shipments leave origin.

Your journey into international food trade doesn’t need to include a $50,000 mistake. With proper preparation, attention to detail, and the right partners supporting your compliance efforts, your products can move smoothly across borders, building your reputation as a reliable trade partner and bringing authentic flavors to eager consumers.

The path from Chinese producer to global tables runs through customs checkpoints where every word on every label matters. Make sure each one counts.